2.5m 3.8m 11m Hdpe Agriculture Shade Net Manufacturing Machine For Orchard

PRODUCT DESCRIPTION

This machine can be customized to produce different net , for example: fruits and vegetables of the packaging bag , with good air permeability.Braided bundles of grass shade net, net, mainly used for greenhouse cultivation, flower tea and animal and plant breeding, scenic area shaded, woven knotless nets, warp knitting machine mesh fabric, chemical fiber fabric, knitted fabric and safety net etc.

| Machine's Type | Mesh Fabric Warp Knitting Machine |

| Bars | 2, 3, 4, 6, 7 or customized |

| Needle Bed | Double Needle Bed |

| Gauge | E3 E6 |

| Knitting Width | 210" 220" or Customized | |

| Application | Different mesh net fabric, like bale netting for grass, vegetables fruit mesh bag, Sunshade Net, building protection net, fish net etc. |

| We are manufactuer which can be according to your different fabric structure to customized machine's functions for you, welcome to contact for further dicussion. |

PRODUCING LINE

MACHINE PICTURE

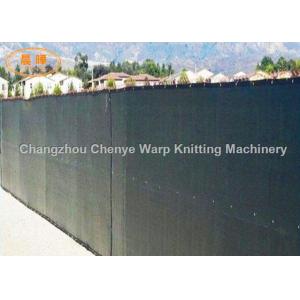

NET SAMPLE

This machine can produce many kinds of net

SHIPPMENT

SERVICE

1. We can dispatch our enginner to your factory to commissioning machine and trainning your enginner.

2. You can dispatch your enginner come to our factory to study how to maintance and fix machine.We will arrange netting factory to teach your enginner study how to produce net for free.

3. Our service team online 24 hours to help you solve problems.

4. Some contries we have office and local enginner to provide you professional service.

5. If we go to your contry to attend exhibition or visit customers,we must go to your factory to maintance machine for free.

COMPANY INTRODUCTION

Chenye is a professional manufacturer of raschel knitting machine and has rich experience in this field. Our company has excellent product quality and excellent service. Chenye is a leading company in mainland China. The product has been sold to

A

FAQ

1. What’s your warranty policy? How we will deal the damages and failures? Do you offer the spare parts?

We offer 1 year warranty on none-consumable parts, but it is limited that machine is applied and operated properly.

We will offer you operation manual + trouble shooting + maintenance guide along with parts list of machines. If you have any damage of the machine, please kindly let us know the damage parts, then we will send the parts to you by DHL or other courier.

Also, we suggest you buy spare parts along with machine which are enough for 1 year to save the courier cost.

If the damage or failure is too serious, we could send our technician to solve the problem.

2. Could you train our stuff? How long it takes? Where? Costs?

Normally, we will train your stuff at your place after the installation of machines. It takes about 2~3 days for the operation and maintenance training,but usually customer ask engineer stay in his factory half a month or one month for training.

We will test the machine before the shipment. So if you think it is necessary to train the stuff in our place, we welcome you to come to our factory for learning the basic knowledge and operation. You only need to pay the accommodation of your stuff.

3. What’s about the installation of the equipment? How long it takes? Are the costs included in offer?

We will test run every machine in our factory before the shipment, and then we will send our technician to your factory for the installation. Generally speaking, it takes about 5-7 days for 1 set of machine. Normally, the cost is not included in the offer.

4. Which raw material could be used for the product?

As we know that HDPE material is the most popular on the market. Also, customers add color masterbatch and UV stabilizer to

change the color and increase the resistance of the net.